High power applications require components that can withstand the extreme conditions and perform reliably. Capacitors, being one of the essential components in such applications, need to be designed to handle high voltage and current levels without compromising on their performance. This is where water cooled capacitors come into play! These advanced types of capacitors are specifically designed to operate under higher temperatures for extended periods by utilizing a cooling system that involves water circulation. In this blog post, we will discuss the advantages of using a water cooled capacitor in high power applications and how it works compared to other conventional capacitors. So let's dive right in!

What is a water cooled capacitor?

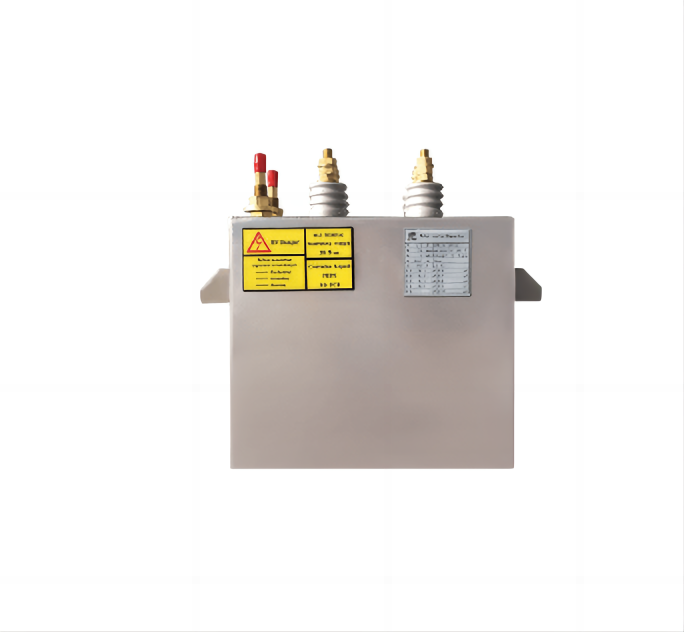

A water cooled capacitor is a type of capacitor that utilizes a cooling system in which water is circulated to dissipate heat generated by the component. Capacitors often generate heat when they are subjected to high voltage and current levels, which can ultimately lead to their failure if not managed properly. However, with water cooled capacitors, this risk is minimized as they operate at lower temperatures compared to conventional capacitors.The design of a water cooled capacitor consists of two basic components: the core and the cooling system. The core is responsible for storing energy while the cooling system circulates water throughout its structure to maintain an optimal temperature range for operation.Water-cooled capacitors have found applications in various industries such as welding equipment, power supplies, induction heating systems and medical devices where high power needs demanding applications require reliable performance over long periods.These types of capacitors offer superior electrical performance while maintaining operational reliability under challenging conditions thanks largely due to their advanced cooling technology that allows them to withstand higher voltages without degrading or overheating.

How does a water cooled capacitor work?

Water cooled capacitors work by using water as a cooling agent to dissipate heat generated during high power applications. These capacitors are designed with internal tubes that allow coolant water to flow through them, removing excess heat and maintaining the capacitor's temperature within safe limits.The coolant water enters the capacitor at one end of the tube and flows out at the other end, taking away heat absorbed from the dielectric material inside. This mechanism ensures that even under extreme conditions, such as in high-power RF amplifiers or induction heating systems, the capacitor stays cool and operates efficiently.To ensure reliable operation, water-cooled capacitors are constructed using materials that resist corrosion and can withstand exposure to different types of fluids. The internal tubing is made of copper or stainless steel for maximum durability while external plumbing connections use rubber o-rings for a secure seal.Water-cooling technology has been used in various industrial applications for decades due to its efficiency in dissipating heat compared with air-cooling mechanisms. In summary, Water cooled capacitors operate by utilizing an innovative design featuring internal tubing that allows coolant water flow through it thereby preventing overheating issues associated with high-power applications.

Advantages of using a water cooled capacitor

Water cooled capacitors offer several advantages over air-cooled ones, making them the preferred choice for high power applications. First and foremost, they can handle higher currents while maintaining a lower temperature due to their efficient cooling system. This means that water cooled capacitors have a longer lifespan and require less maintenance.In addition, water has a higher heat capacity than air, which allows it to absorb more heat from the capacitor. As a result, water cooled capacitors are able to operate at higher voltages without overheating or causing damage to other components in the circuit.Another advantage of using water cooled capacitors is their compact size. They take up much less space compared to their air-cooled counterparts since they do not need bulky finned heat sinks for cooling purposes.Water cooled capacitors are also more environmentally friendly as they consume significantly less energy than air-cooled ones. The reduced energy consumption results in lower greenhouse gas emissions and decreased carbon footprint.The use of water cooled capacitors in high power applications offers numerous benefits such as improved performance, increased efficiency and reduced environmental impact.

Conclusion

High power applications require stable and reliable components for optimal performance. A water cooled capacitor provides many advantages over traditional air-cooled capacitors in these types of applications. The use of water as a cooling medium allows for a more efficient heat dissipation process, resulting in higher power ratings and longer lifespan.Additionally, the ability to customize the size and shape of a water cooled capacitor makes it ideal for compact designs where space is limited. With its superior performance capabilities and versatility, it's clear that a water cooled capacitor can provide significant benefits to any high power application.As technology continues to advance, we can expect to see even more innovative solutions emerging in the field of electrical engineering. But for now, when it comes to achieving maximum efficiency and reliability in high power applications – using a water cooled capacitor is definitely worth considering!Welcome to contact us,if you need.[email protected],[email protected]